Step-By-Step Guide to Recycling Metal for Your Manufacturing Business

June 7, 2024

Optimizing your metal recycling process involves several key steps that can significantly enhance efficiency and profitability. Start by conducting a detailed audit to quantify and document the types of metal waste your facility produces. Establish clearly labeled collection points to streamline the sorting process and ensure convenience. Selecting the right recycling equipment tailored to the specific types and volumes of metal waste is crucial. Partnering with certified recyclers not only ensures compliance but also streamlines the entire recycling process. To maximize profit margins, research market prices and negotiate with multiple buyers. This blog will guide you through each of these steps, helping you transform your metal recycling process into a more efficient and profitable operation.

Assessing Your Metal Waste

To effectively recycle metal, you first need to assess the types and quantities of metal waste your manufacturing business generates. Start by conducting a thorough audit of your metal waste. This involves walking through your production lines and noting where and how metal waste is produced. Identify the various processes—from cutting and shaping to assembly—that contribute to scrap metal accumulation.

Next, quantify the waste. Use precise measurements such as weight or volume to gauge how much metal scrap is being produced daily, weekly, or monthly. Tracking these metrics helps you understand the scale of your recycling needs and can highlight areas for waste reduction.

Document the specific types of metals you’re discarding. Common industrial metals include aluminum, steel, copper, and brass. Knowing exactly what types of metals are in your waste stream is essential for the next steps in the recycling process.

Sorting and Categorizing Scrap

Begin by sorting your scrap metal into distinct categories based on type and quality. Separate ferrous metals, like steel and iron, from non-ferrous metals such as aluminum, copper, and brass. Ferrous metals are magnetic and usually heavier, while non-ferrous metals are lighter and non-magnetic. Use a magnet to quickly identify ferrous metals; if it sticks, it’s ferrous.

Further categorize each type by quality and condition. Clean, uncontaminated metal fetches a higher recycling value. Remove any attachments, like plastic, rubber, or other non-metal materials. If the scrap is painted or coated, consider whether it’s feasible to strip these layers off.

Identify and isolate any high-value metals, such as copper or brass, which can significantly enhance your recycling revenue. Make sure that these metals aren’t mixed with lower-value ones. For aluminum, sort by alloy type if possible, as different alloys have different recycling processes and values.

Setting Up Collection Points

Establish convenient collection points throughout your facility to streamline the recycling process and encourage employees to participate. Start by identifying high-traffic areas where scrap metal is frequently generated. Place clearly labeled bins in these spots to make it easy for workers to dispose of metal waste without disrupting their workflow.

Guarantee that the bins are easily accessible and differentiated by type of metal, such as aluminum, steel, and copper. This helps in keeping the sorting process efficient and reduces contamination. Use color-coded or well-marked containers to avoid confusion. Regularly monitor these collection points to make sure they don’t overflow and maintain a tidy appearance.

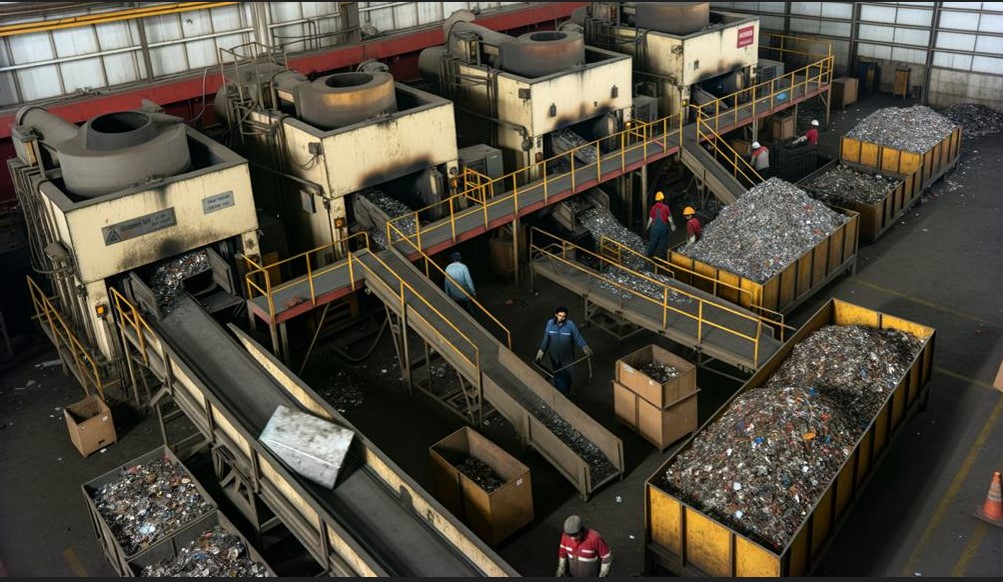

Choosing Recycling Equipment

Selecting the right recycling equipment is essential for optimizing your metal recycling process and ensuring maximum efficiency. Begin by evaluating the types of metals you’ll be recycling. Different metals require different machinery; for instance, ferrous metals need magnetic separators, while non-ferrous metals benefit from eddy current separators.

If you’re managing large quantities, investing in high-capacity shredders and balers can save time and labor. Smaller operations might only need compact, versatile equipment. Balers help compress metal into manageable sizes, reducing storage space and transportation costs.

Don’t forget to assess the ease of maintenance and operational costs. Equipment that’s cheaper upfront might end up costing more in the long run due to frequent repairs or high energy consumption. Look for machines with good warranties and reliable customer support.

Safety is another important factor. Choose equipment with built-in safety features to protect your employees from accidents. Automated systems can reduce human error and increase overall safety.

Think about future scalability. As your business grows, your equipment should be able to handle increased loads without requiring a complete overhaul.

Partnering With Recyclers

Collaborating with reputable recyclers can greatly enhance the sustainability and cost-effectiveness of your manufacturing operations. First, identify recyclers who specialize in the types of metal waste your business generates. Not all recyclers handle every kind of metal, so make sure they can process the specific materials you produce. Look for certifications and industry accreditations to verify their importance and compliance with environmental standards.

Here’s a quick comparison to help you evaluate potential buyers:

| Criteria | Local Buyers | National Buyers | International Buyers |

| Transportation Costs | Low | Moderate | High |

| Payment Terms | Faster | Moderate | Slower |

| Market Price Stability | Variable | Stable | Variable |

Consider these factors when deciding which buyers to prioritize. Local buyers might save you on transportation costs, but national or international buyers could offer better prices. Always weigh the pros and cons to make sure you’re making the best decision for your business. By focusing on these key aspects, you’ll find buyers more efficiently and boost your overall profitability.

Next, establish a clear communication channel with your chosen recycler. Regular updates on the types and quantities of metal waste you have can help them plan more efficiently, ensuring timely pickups and minimizing disruptions to your operations. A good recycler will also provide you with detailed reports on how your waste is being processed, reinforcing your commitment to transparency and sustainability.

Finally, negotiate terms that benefit both parties. This could include consistent pickup schedules, volume-based pricing, or even on-site collection services. By fostering a strong partnership, you can streamline your recycling process, reduce waste management costs, and contribute positively to the environment.

Frequently Asked Questions

What Certifications Are Needed for a Metal Recycling Business?

You’ll need several certifications for a metal recycling business, including local business licenses, environmental permits, and possibly OSHA compliance. Check specific state and federal requirements to make sure you meet all necessary regulations and standards.

How Can Recycled Metal Impact Product Quality and Performance?

Recycled metal can impact product quality and performance by maintaining strength and durability while reducing costs. You might notice slight differences in consistency, but modern recycling techniques guarantee high-quality standards are met for most applications.

Are There Any Government Grants for Metal Recycling Initiatives?

Yes, you can find government grants for metal recycling initiatives. These grants often aim to promote sustainability and reduce waste. Check local, state, and federal programs for specific opportunities that fit your business needs.

What Are the Environmental Benefits of Recycling Metal?

Recycling metal reduces energy consumption, lowers greenhouse gas emissions, and conserves natural resources. You’ll help minimize landfill waste and promote sustainability. It’s an essential step toward a healthier planet and a more eco-friendly business.

How Do I Ensure Compliance With Local Recycling Regulations?

You need to research local recycling laws, contact your local waste management authority, and stay updated on regulations. Regularly train your staff on compliance and maintain detailed records to guarantee adherence to all requirements.

Streamline Your Metal Recycling Process with Greenway Metal Recycling

By following these steps, you can streamline your metal recycling process and boost your manufacturing efficiency. Start by assessing your waste and sorting it properly. Set up collection points and choose the right equipment for efficient metal processing. Partner with Greenway Metal Recycling for your industrial scrap needs to ensure compliance and reliability. Selling your recycled metal for a profit will reduce costs and promote sustainability. Begin today and see the positive impact on both your business and the environment.